A crafting technique is known as 3D printing, or additive manufacturing, in which a digital file is used to create a tangible, three-dimensional object. In the 3D printing process, the printer sequential layers of material are laid down until object creation is completed. In this read, we’ll dive into the inner workings of it, explore the software that makes it tick, and discover the fascinating array of applications that bring this technology to life.

What is 3D Printing?

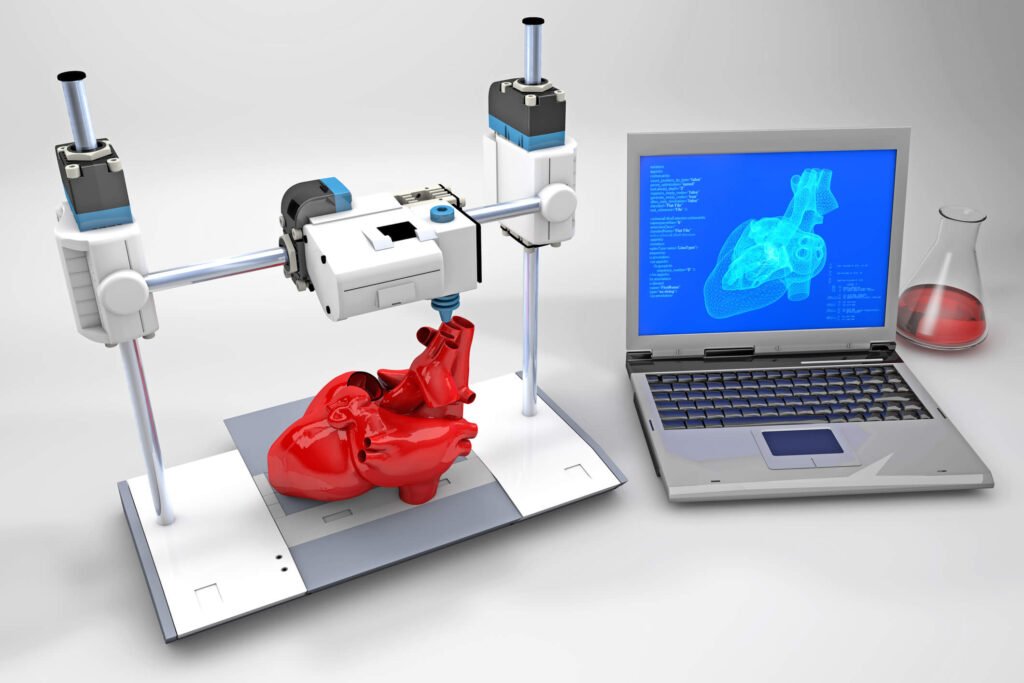

It manufactures physical objects from Digital files. It’s a creative process where a real, tangible object is crafted layer by layer, starting from a digital blueprint.

Understanding 3D Printing

Since its introduction, it has not only boosted manufacturing productivity but also holds the promise of revolutionizing entire industries like manufacturing, logistics, and inventory management in the long run, especially if seamlessly integrated into large-scale production processes.

Presently, 3D printing might not be the go-to for mass production due to its relatively slower speeds. Yet, its true prowess shines in accelerating the prototyping phase for small-scale manufacturers, slashing costs, and swiftly bringing innovative products to the market. This means quicker turnarounds from concept to sale, making it a game-changer for nimble businesses.

With 3D printing, we can craft intricate and detailed shapes while conserving materials compared to traditional methods like drilling, welding, or injection molding. This not only speeds up prototype development but also makes innovation more accessible, encouraging experimentation and empowering aspiring product-based startups without breaking the bank.

How does 3D Printing Work

The ISO/ASTM 52900, which lays down the groundwork for the basic principles and terms in additive manufacturing, breaks down its methods into seven clear categories. Each of these printing types operates in its unique way, adding a touch of individuality to the world of manufacturing.

Printing a 3D object is a unique journey influenced by factors like the printing method, object size, material choice, desired quality, and setup configuration. The timeframe for 3D printing can vary significantly, ranging from just a few minutes to a span of several days.

The different types of 3D printing are:

- Powder bed fusion

- VAT photopolymerization

- Binder jetting

- Material jetting

- Fused deposition modeling

- Sheet lamination

- Direct energy deposition

Top 7 3D Printing Software

Delving into the realm of 3D printing, we find a close alliance with software, playing a crucial role in designing, slicing, and controlling the entire printing process. Join us as we explore some of the top-notch 3D printing software that caters to diverse applications.

- MatterControl 2.0

- Tinkercad

- Blender

- UVTools

- WebPrinter

- Ultimaker Cura

- Simplify3D

Industrial Uses

From revolutionizing the sleek designs of cars to enhancing the construction of aircraft fuselages, 3D printing has become a game-changer in the manufacturing realm. Take Boeing, for instance, which is incorporating 3D-printed titanium components into the assembly of its 787 Dreamliner, showcasing the transformative potential of this technology in the aviation sector. General Electric, too, has demonstrated the power of 3D printing by crafting a helicopter engine with just 16 parts instead of the traditional 900, offering a glimpse into a future where supply chains could be streamlined and simplified.

In the realm of medicine, it is making waves by tailoring implants for individual patients, with future potential to craft organs and body parts using this groundbreaking technology. Stepping into the world of fashion, giants like Nike, Adidas, and New Balance are incorporating 3D printing to fashion avant-garde footwear designs. Meanwhile, in construction, innovative companies worldwide are pioneering the use of it to create building materials, allowing for the construction of robust homes in just 24 hours at a fraction of the cost compared to traditional methods

When crafting hearing aids, 3D printing has become the go-to method, speeding up the manufacturing process and allowing for personalized, custom-fit devices. Audiologists employ 3D scanners to create unique prototypes based on individual scans, which manufacturers then fine-tune and seamlessly translate into fully printed, tailor-made hearing aids.

Takeaway

Think of ‘3D printing’ as a magical toolbox filled with various technologies and methods, all working together to create a vast array of components using different materials. What ties them together is this cool layer-by-layer method – no subtracting, molding, or casting involved. As 3D printing becomes more affordable and efficient, it’s weaving its way into every nook and cranny of different industries, bringing innovation and possibilities right to our fingertips.